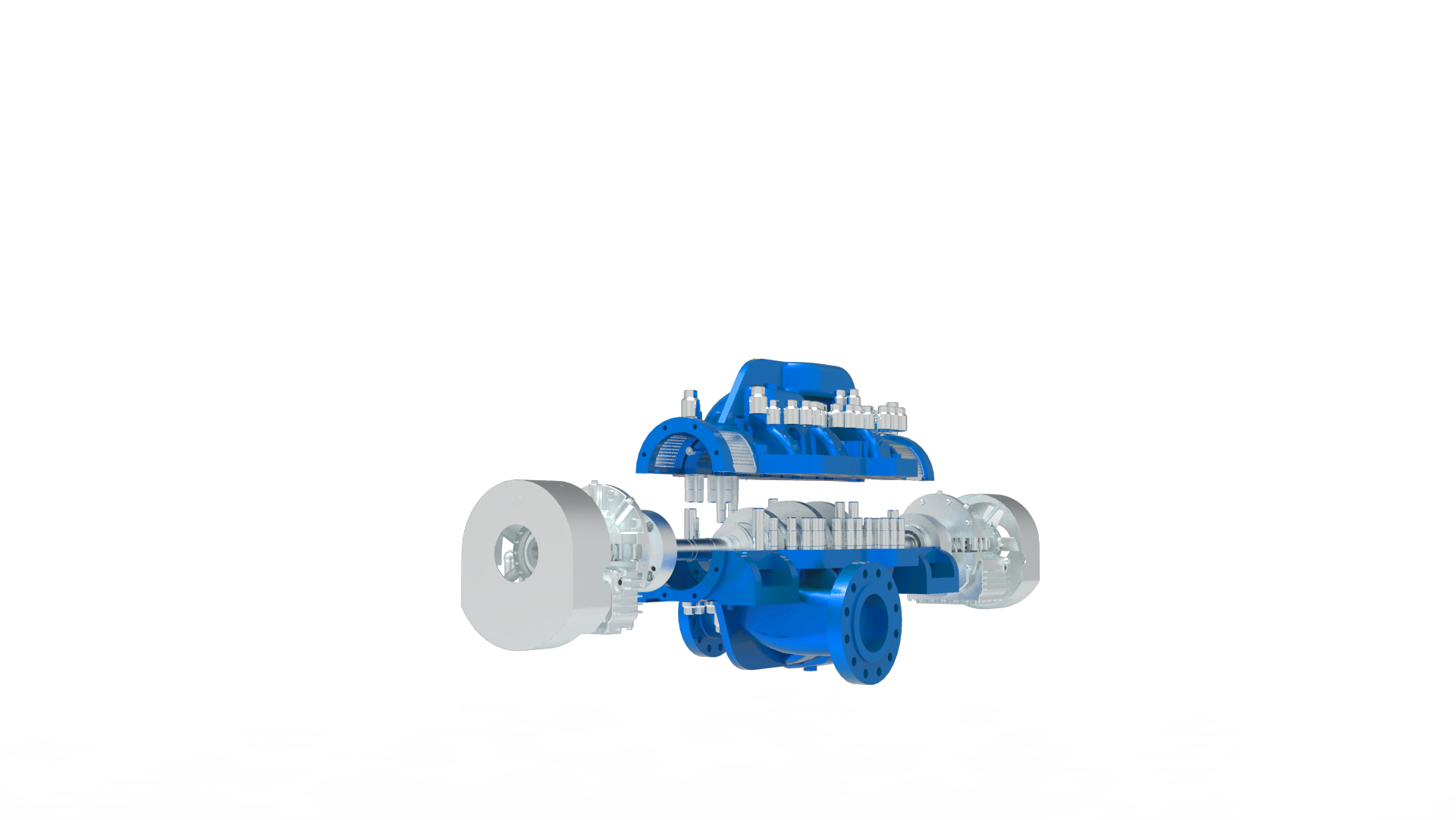

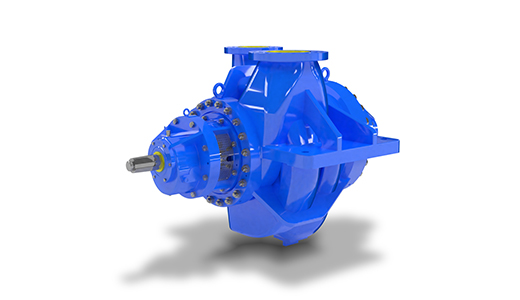

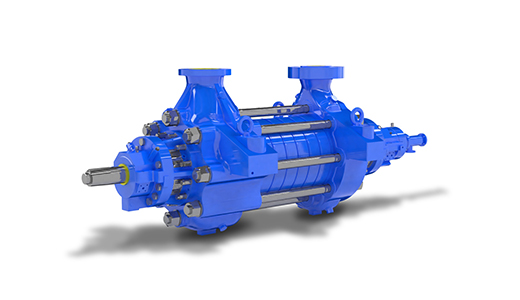

API Standard Pump BB3 – KB3S/KB3D

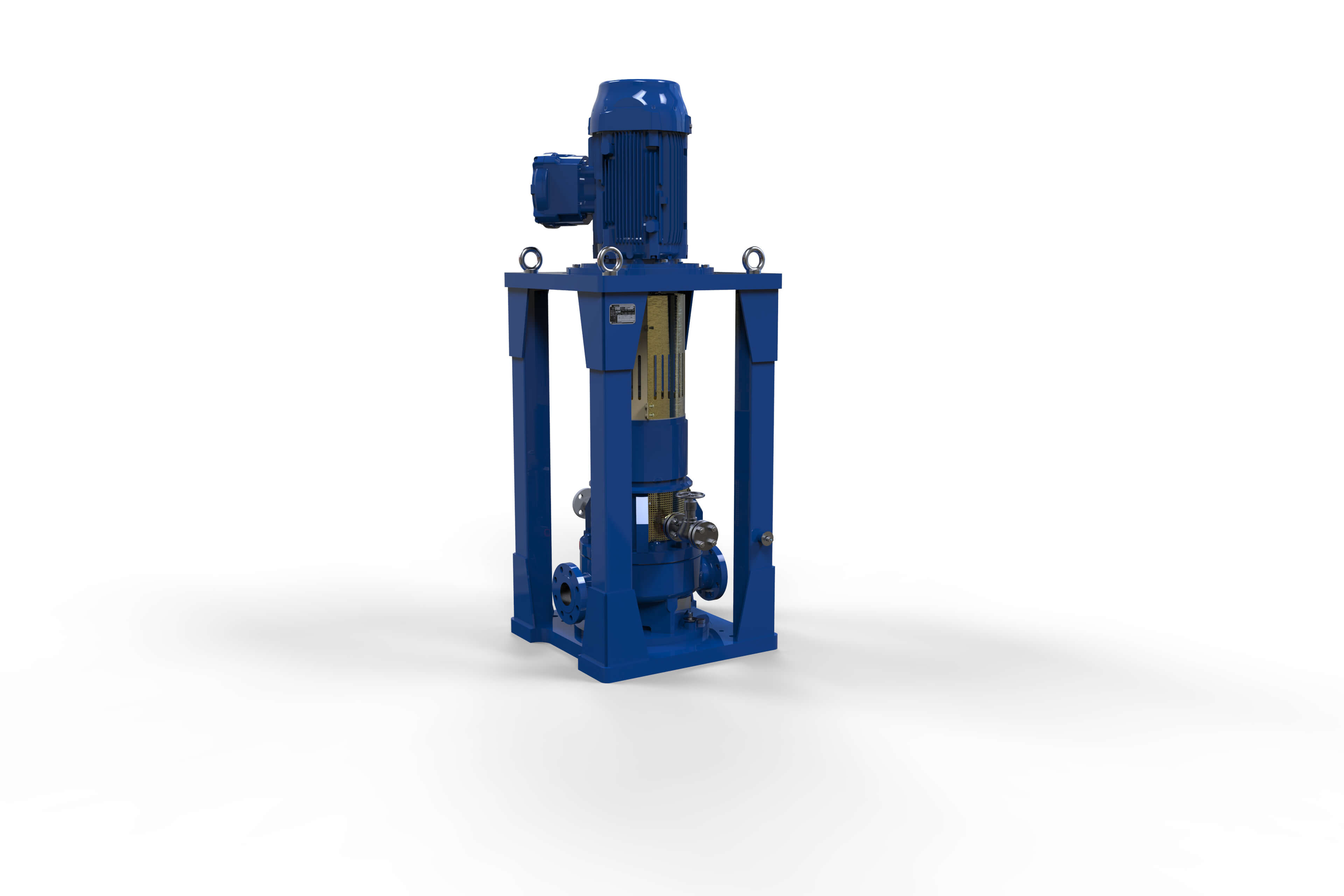

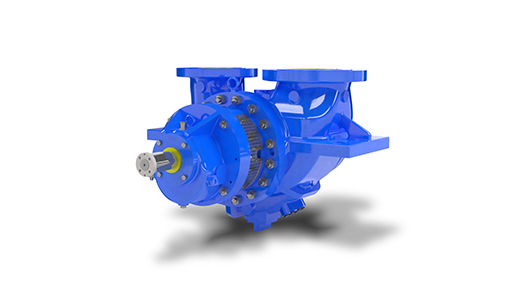

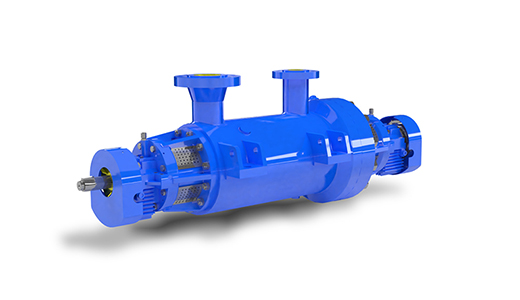

The KB3S / KB3D is an API BB3 type process pump with near centerline supported heavy-duty axial split casing. This pump’s design offers high performance and efficiency during stringent operating conditions. It is manufactured as per API 610. The KB3S/KB3D pumps come with a pump head Upto 1840 m with an option of upgrading to a higher capacity and head for operations at higher speeds. The pumps operate at a discharge pressure of up to Cl. 2500, nozzle orientation as side-side. The direction of rotation is clockwise from the coupling end. The KB3S / KB3D pump is suitable for applications in oil refineries and petrochemical industries, descaling operations in steel industries, oil wells, petroleum product applications, and chemical and process plants, pipeline applications.

- Design and manufacture as per API 610

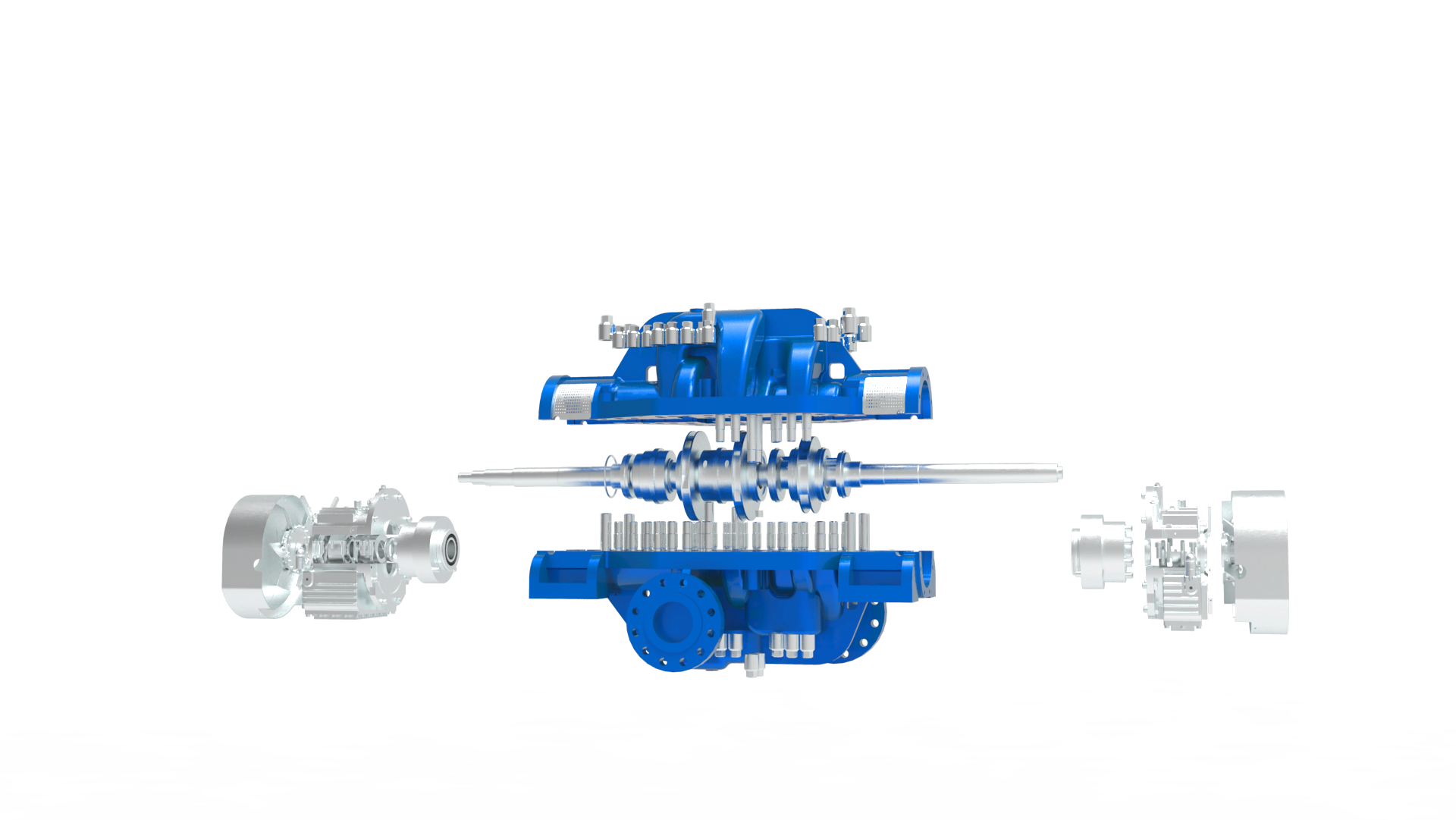

- Near centerline supported heavy duty axial split casing design to ensure high reliability under high pressure applications

- Easy inspection and repair maintenance of bearings and mechanical seal after removal of coupling spacer only. The rotor can be removed by disassembling upper half casing without disturbing suction / discharge piping and driver

- Low NPSH requirement is achieved with first stage double suction impeller in KB3D pumps

- High pressure fluid handling in oil refineries and petrochemical industry

- MP and HP boiler feed applications

- Descaling application in steel industries

- Sea water injection application in oil wells

- Mine Dewatering

- Petroleum product Pipeline booster applications

- Pump as hydraulic power recovery turbine in chemical and process plants

| Parameters | KB3S/KB3D |

| Capacity (m3/hr) | Upto 1750 |

| Head (m) | Upto 1840 |

| Temperature Range ℃ | -104 to 200 |

| Discharge Pressure | Upto Cl. 2500 # |

| Suction Pressure kg/cm2(g) | Upto 80 |

| Nozzle Orientation (Suc./Dis.) | Side-Side |

| Standard Motor Synchronous Speeds (rpm) | 1000 / 1200 / 1500 / 1800 / 3000 / 3600 |

| Max. Operating Speed (rpm) | 7000 |

| Direction of Rotation | Clockwise when viewed from coupling end |

| Flange Ratings | Cl. 300 / 600 /900 / 1500 / 2500 |

Products

Products  Contact

Contact