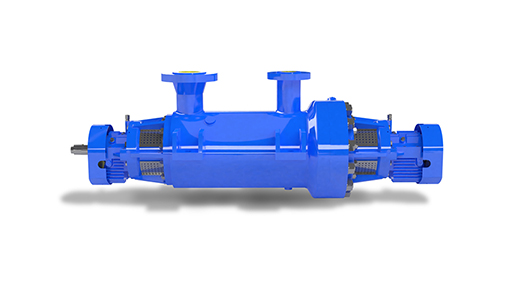

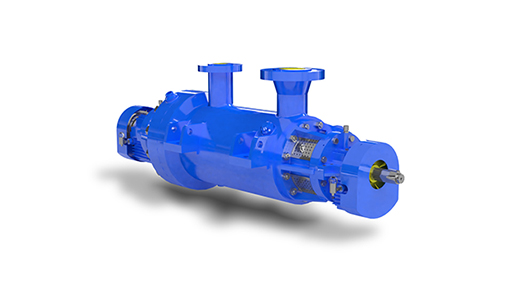

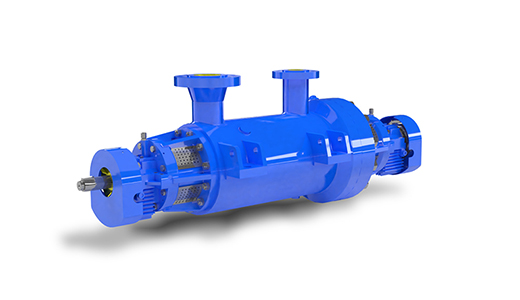

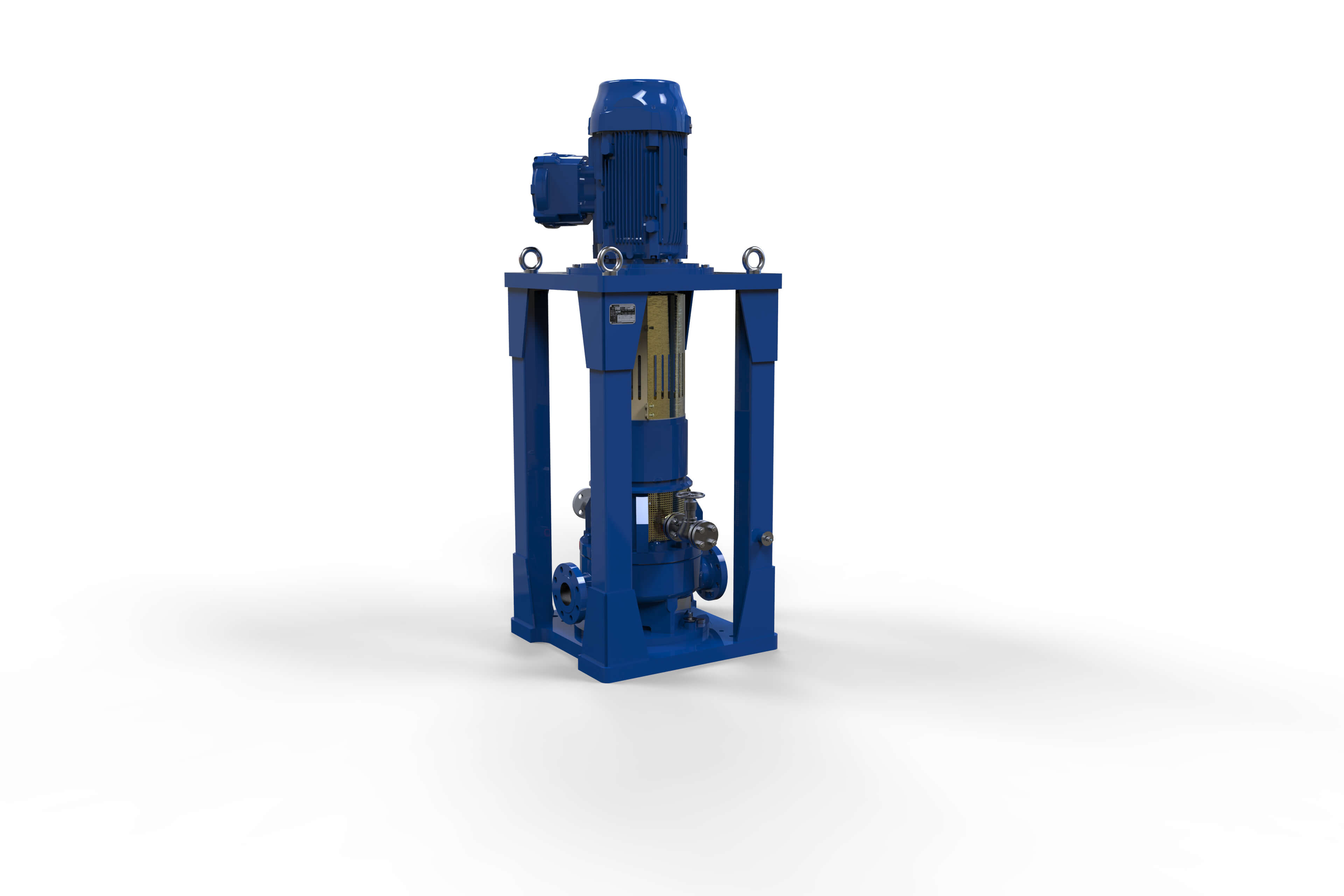

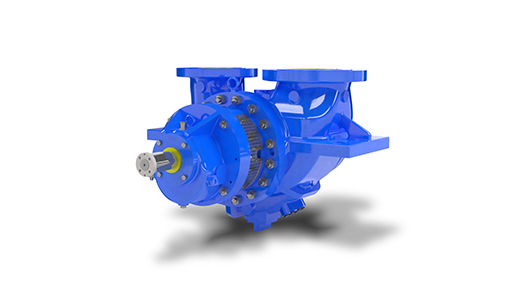

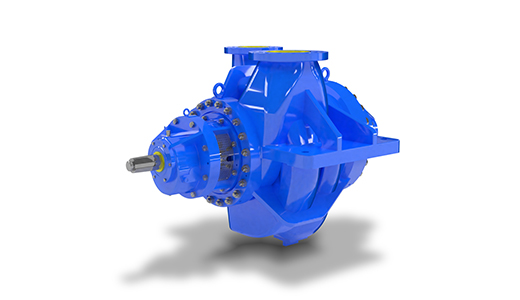

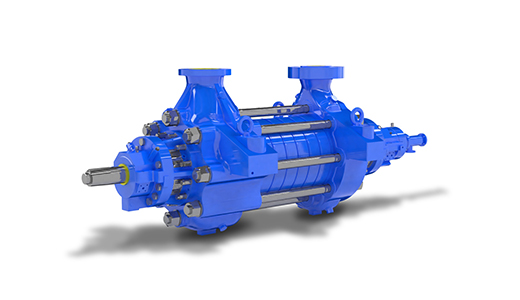

API Standard Pump BB5 – DCS (KBDS) / DCD (KBDD)

The DCS(KBDS)/DCD (KBDD) is a BB5 type multistage pump with Centerline support and a heavy-duty double casing diffuser design. This pump is suitable for high pressure and high-temperature operations. It is manufactured as per API 610. The range covers a pump head of Upto 2500 m, expandable to higher heads as per requirement. The pump offers a discharge pressure of up to Cl. 2500#. Nozzle orientation as the top-top, side-top and side-side, the direction of rotation is clockwise when viewed from the coupling end. The DCS (KBDS)/DCD (KBDD) pump is suitable for applications in oil refineries and petrochemical industries, boiler feed applications, hydrocarbon and liquid gas transfer applications, petroleum product pipeline booster applications, mine dewatering, oil well, and chemical and process plants. The parts of this pump family are designed to offer maximum interchangeability to serve customer requirements.

- Design and manufacture as per API 610

- Multistage centerline supported heavy duty double casing diffuser design for handling high pressure and high temperature applications

- Easy inspection and repair maintenance of bearings and mechanical seal after removal of coupling spacer only. The cartridge (assembly of all parts except outer casing) can be removed without disassembling suc / dis piping and driver

- Axial thrust balancing is with the help of options like piston & balance disc, double piston or straight piston to suit various applications

- Low NPSH requirement is achieved with first stage double suction impeller in DCD pumps

- Pump family designed to have max. parts interchangeability

- High pressure fluid handling in oil refineries and petrochemical industry

- MP and HP boiler feed applications

- Light hydrocarbon and liquid gas transfer applications

- Sea water injection application in oil wells

- Mine Dewatering

- Petroleum product Pipeline booster applications

- Pump as hydraulic power recovery turbine in chemical and process plants

| Parameters | DCS (KBDS) / DCD (KBDD) |

| Capacity (m3/hr) | Upto 750

(Note 1) |

| Head (m) | Upto 2500

(Note 1) |

| Temperature Range ℃ | -104 to 450 |

| Discharge Pressure rating | Upto Cl. 2500 # |

| Suction Pressure kg/cm2(g) | Upto 80 |

| Nozzle Orientation (Suc./Dis.) | Top-Top & Side-Top, Side – Side |

| Standard Motor Synchronous Speeds (rpm) | 1500 / 1800 / 3000 / 3600 |

| Max. Operating Speed (rpm) | 7000 |

| Direction of Rotation | Clockwise when viewed from the coupling end |

| Flange Ratings | Cl. 300 / 600 /900 / 1500 / 2500 |

Note-1 : More higher capacity and head is possible when pumps are operated at higher speeds.

Products

Products  Contact

Contact